Media converters could prove essential as industrial Ethernet rises

By Max BurkhalterAugust 31, 2016

Industrial Ethernet technologies are changing the way organizations in process industries connect operations across operational boundaries. As Ethernet is deployed across various parts of industrial facilities, data can more easily move between these disparate areas and interact with a wide range of systems. All of this innovation is only possible, however, if strategic network upgrades are made to support data integration between operational channels. Industrial Ethernet simplifies this process by eliminating compatibility barriers that are common in more traditional industrial network setups.

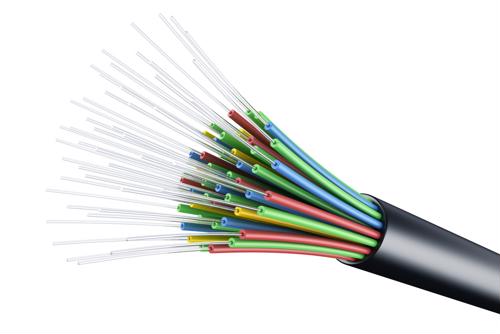

Instead of needing to mix fieldbus, serial and other types of connections alongside traditional Ethernet used for line-of-business, industrial Ethernet allows diverse systems to operate under a single protocol. This simplifies many of the switching and routing difficulties associated with establishing an industrial network, but cabling can also present challenges as infrastructure must be rolled out over extended distances, in harsh environments and to reach a wide range of device types. A recent Technavio study found that while copper wiring is still dominant in industrial networks, fiber-optic cabling is gaining momentum fast.

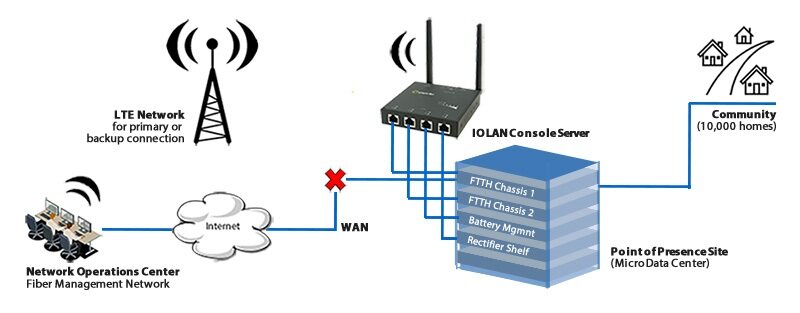

Network technologies are becoming essential as industrial operations advance.

Cabling in an industrial settings

According to the study, copper cabling boasts a 77 percent market share in industrial Ethernet networks. This dominance is fueled by increased investments in CAT 6 and CAT 6a cables, as these solutions support data transmission speeds of up to 1 Gbps. The problem is that 1 Gbps is the top end of the bandwidth available with CAT 6 and CAT 6a cables, while fiber offers a few key advantages, including:

- The capacity to support data rates far exceeding 1 Gbps.

- The ability to extend over longer distances without signal degradation.

- The resilience to withstand exposure to electromagnetic and radio interference without performance problems.

These factors add up to make fiber-optic cabling an ideal option in many industrial settings, and the study found that fiber is already extremely popular in the oil and gas and paper and pulp sectors. While fiber-optic cabling solutions are rising, copper is expected to maintain its place of dominance in the market until 2020.

Bharath Kanniappan, a lead automation research analyst for Technavio, explained that strategic network investments provide vital intelligence within industrial operations.

"Many companies in the manufacturing sector are relying on Ethernet technology for network intelligence and its robust cables and connectors, which provide reliable and secure data," said Kanniappan. "Ethernet technology data transfer rates range from 10 Mbps to 10 Gbps Ethernet."

Data connectivity is critical in modern manufacturing environments.

Leveraging fiber without taking on excess costs

Industrial organizations must derive a return on investment from their network projects. Initiatives need to align with business goals and lead to direct gains. Copper cabling is an attractive option here because it is generally significantly less expensive than fiber and still meets the data transmission requirements of the vast majority of workflows. However, data-rich services are becoming increasingly common in a wide range of sectors, including manufacturing, creating a climate in which fiber is a prime option.

As organizations work to align their network capabilities with operational demands, they can mix-and-match fiber to gain the best possible price-to-performance ratio. Fiber-to-Ethernet media converters can be especially beneficial in three operational climates:

1. Long cable runs

Extended cable runs, such as getting wiring out to surveillance cameras or interconnecting multiple buildings, can get expensive quickly when using copper cables. Adding in extenders, switches and other solutions not only demands extra hardware investments but also introduces complexity that can make any future moves, adds and changes more difficult. All told, this can lead to higher total costs of ownership when making extended cable runs using copper. Conversely, fiber can handle long distances without the need for extra hardware throughout the network link - all you need is a media converter to interconnect with Ethernet at the end.

The simplicity offered by fiber combines with performance advantages to future-proof the infrastructure and allow for a long life cycle before replacement becomes necessary.

"Operational gains can justify the expense of fiber-optic cabling."

2. Backhaul and interconnects

Industrial networks can get incredibly complex as data moves between multiple facilities and environments to support everyday operations. This results in a situation in which data can bottleneck in network links that are particularly busy, leading to ongoing performance challenges and making it difficult to align business and production requirements.

Identifying parts of the network where data will converge in large quantities and strategically deploying fiber in those areas can eliminate longstanding performance problems and allow for operational gains that justify the expense of fiber-optic cabling.

3. Areas of interference

In most cases, fiber-optic cables use LED-based lasers to transmit signal through the wire. This stands in stark contrast to copper, which depends on electromagnetic signals. Production environments with large quantities of radio signal, devices that emit electromagnetic interference are problematic for copper. It is also worth noting that copper cables can be adversely impacted by issues like heat and vibration as the physical nature of moving signal over a copper wire makes it more sensitive to those conditions.

Fiber's use of lasers makes it more resilient to conditions that would typically be associated with industrial environments, making it an ideal option in environments where interference is expected.

Manufacturers are facing growing network challenges as they work to implement a wide range of data types into everyday operations. Blending fiber-optic cabling with traditional copper wires can help organizations get the most performance out of their network in the most cost-efficient way. Combining specialized industrial Ethernet switches with fiber-to-Ethernet media converters can make this possible, maximizing ROI potential.

Perle has an extensive range of Managed and Unmanaged Fiber Media Converters to extend copper-based Ethernet equipment over a fiber optic link, multimode to multimode and multimode to single mode fiber up to 160km.