PP-RJ DIN Rail Patch Panels with Surge Protection

Easily connect field and control cabinet cabling

- 10/100/1000 Mbps

- RJ45 to RJ45, IDC, Push-in or Screw Terminal Block

- Wiring space covered with front panel cover

- Tool-free shield contacting with strain relief

- Compact design with quick and easy mounting

- Extended temperature range of -40°C to +75°C

- Integrated surge protection to ensure high system availability

Ethernet patch panels make the connection between field cabling and control cabinet cabling quick and easy. In environments vulnerable to voltage surges, a PP-RJ-F DIN Rail Patch Panel is ideal for installation inside control panels and distribution cabinets where one-to-one simplified connections need to be made in environments. A standard Ethernet patch cable is used between the patch panel and the control cabinet equipment, such as switches, PLCs and routers. Through ICD, Push-in, Screw or RJ45 connectors, field wiring is easily connected to the patch panel and protected inside a covered wiring space. The cable shielding is connected quickly and easily, without tools, while simultaneously ensuring strain relief. This simplifies installation of the field cable and saves a great deal of time during installation. PP-RJ DIN Rail Patch Panels provide the perfect mix of density and flexibility to decrease network risk and improve cable organization in scalable deployments with constricted spaces.

Ideal applications for PP-RJ-F DIN Rail Patch Panels

- Inside equipment cabinets with DIN rails

- Alongside Industrial Ethernet switches and RJ45 (Ethernet or Serial) PLCs

- Alongside other DIN Rail RJ45 (Ethernet or Serial) control devices

- Where growth from one to many ports is needed to support high-density installations. Multiple one port DIN Rail Patch Panels can installed side-by-side to grow, as required by the customer application.

Benefits of PP-RJ-F DIN Rail Patch Panels

| Integrated Surge Protection | The integrated surge protection protects the devices and the application against sudden high voltages in the field data cables. |

| Shield current monitoring | The cable shield current monitoring can be used for diagnostics. An LED indicates if there are differences in potential or other shield currents caused by EMC.  |

| Multiple connection technologies | For greater flexibility and time savings during installation you can choose between IDC, Push-in, Screw, and RJ45 connections.

|

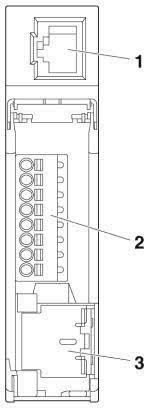

| Covered cable wiring space | A hinged cover protects the wiring space on the field cable side with connection terminal blocks and shield contacting. This ensures a uniform installation pattern. In addition to this visual extra, the sensitive connection wires are protected from external influences. |

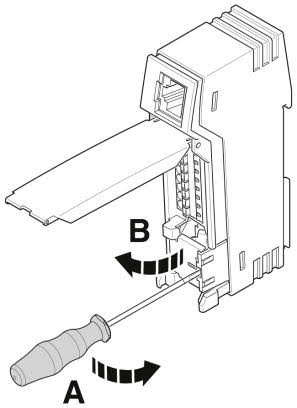

| Quick tool-free shield connection with no loose parts | The cable shielding can be connected to the device quickly and easily without tools – with strain relief assured at the same time. Simply lay the cable in the shaft provided, close the shroud and, you're done.  |

| DIN Rail Enclosure | Easily mount on a DIN rail or inside distribution boxes using native DIN Rail enclosure with grounding clip. No need for add-on brackets. |

| Low profile design | The low-profile design minimizes cable bend radius in shallow enclosures where space is a premium as well as providing secure cable strain relief. |

Specifications

HTSUS Number:

8536.90.8085

UNSPSC Code:

43223309

ECCN:

EAR99

Serial interface

Interface 1

Ethernet interface, 10/100/1000Base-T(X) according to IEEE 802.3u

Connection method

PP-RJ-RJ-F

27030208

RJ45 socket

PP-RJ-SC-F

27030218

Screw terminal block

PP-RJ-SCC-F

27030228

Push-in connection

PP-RJ-IDC-F

27030238

IDC connection

Transmission length

100 m (including patch cables)

Pin assignment

1:1

Serial transmission speed

10/100/1000 Mbps

Maximum output current

725 mA (PoE)

Current carrying capacity

≤ 1.5 A (≤ 60 W (PoE+))

Maximum output power

60 W

Interface 2

Ethernet interface, 10/100/1000Base-T(X) according to IEEE 802.3u

Connection method

RJ45 CAT5e

Conductor cross section solid min.

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

0.14 mm²

PP-RJ-SCC-F

27030228

0.2 mm²

PP-RJ-IDC-F

27030238

0.14 mm²

Conductor cross section solid max.

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

1.5 mm²

PP-RJ-SCC-F

27030228

1.5 mm²

PP-RJ-IDC-F

27030238

0.34 mm²

Conductor cross section flexible min.

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

0.14 mm²

PP-RJ-SCC-F

27030228

0.2 mm²

PP-RJ-IDC-F

27030238

0.14 mm²

Conductor cross section flexible max.

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

1.5 mm²

PP-RJ-SCC-F

27030228

1.5 mm²

PP-RJ-IDC-F

27030238

0.34 mm²

Conductor cross section AWG min.

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

28

PP-RJ-SCC-F

27030228

26

PP-RJ-IDC-F

27030238

26

Conductor cross section AWG max.

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

16

PP-RJ-SCC-F

27030228

16

PP-RJ-IDC-F

27030238

22

Torque

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

0.22 Nm ... 0.25 Nm

PP-RJ-SCC-F

27030228

PP-RJ-IDC-F

27030238

Stripping length

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

5 mm

PP-RJ-SCC-F

27030228

8 mm

PP-RJ-IDC-F

27030238

Wire diameter incl. insulation

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

PP-RJ-SCC-F

27030228

PP-RJ-IDC-F

27030238

1.6 mm (Terminal block is tested with PVC insulation - other insulation materials available on request)

Ambient conditions

Ambient temperature (operation)

-40°C ... 75°C

Ambient temperature (storage/transport)

-40°C ... 85°C

Permissible humidity (operation)

10 % ... 95 % (non-condensing)

Altitude

5000 m (For restrictions see manufacturer's declaration) / 2000 m (ATEX approval)

Degree of protection

IP20 (Manufacturer's declaration)

General

Electrical isolation

FE // Ethernet

Electromagnetic compatibility

Conformance with EMC Directive 2014/30/EU

Net weight

124.2 g

Housing material

Plastic

Color

Gray

MTTF

PP-RJ-RJ-F

27030208

3281 Years (SN 29500 standard, temperature 25°C, operating cycle 21 % (5 days a week, 8 hours a day))

PP-RJ-SC-F

27030218

3268 Years (SN 29500 standard, temperature 25°C, operating cycle 21 % (5 days a week, 8 hours a day))

PP-RJ-SCC-F

27030228

3281 Years (SN 29500 standard, temperature 25°C, operating cycle 21 % (5 days a week, 8 hours a day))

PP-RJ-IDC-F

27030238

3281 Years (SN 29500 standard, temperature 25°C, operating cycle 21 % (5 days a week, 8 hours a day))

PP-RJ-RJ-F

27030208

1245 Years (SN 29500 standard, temperature 40°C, operating cycle 34.25 % (5 days a week, 12 hours a day))

PP-RJ-SC-F

27030218

1238 Years (SN 29500 standard, temperature 40°C, operating cycle 34.25 % (5 days a week, 12 hours a day))

PP-RJ-SCC-F

27030228

1245 Years (SN 29500 standard, temperature 40°C, operating cycle 34.25 % (5 days a week, 12 hours a day))

PP-RJ-IDC-F

27030238

1245 Years (SN 29500 standard, temperature 40°C, operating cycle 34.25 % (5 days a week, 12 hours a day))

PP-RJ-RJ-F

27030208

472 Years (SN 29500 standard, temperature 40°C, operating cycle 100 % (7 days a week, 24 hours a day))

PP-RJ-SC-F

27030218

468 Years (SN 29500 standard, temperature 40°C, operating cycle 100 % (7 days a week, 24 hours a day))

PP-RJ-SCC-F

27030228

472 Years (SN 29500 standard, temperature 40°C, operating cycle 100 % (7 days a week, 24 hours a day))

PP-RJ-IDC-F

27030238

472 Years (SN 29500 standard, temperature 40°C, operating cycle 100 % (7 days a week, 24 hours a day))

Degree of pollution

2

Overvoltage category

II

Conformance

CE-compliant

ATEX

II 3 G Ex nA nC IIC T4 Gc X (Please follow the special installation instructions in the documentation!)

UL, USA

UL 60079-0 Ed. 6 / UL 60079-15 Ed. 4

UL, USA/Canada

Class I, Zone 2, AEx nA IIC T4, Ex nA IIC Gc X T4 / Class I, Div. 2, Groups A, B, C, D

UL, Canada

CSA 22.2 No. 60079-0 Ed. 3 / CSA 22.2 No. 60079-15:16

Standards and Regulations

Electromagnetic compatibility

Conformance with EMC Directive 2014/30/EU

Type of test

Vibration resistance in acc. with EN 60068-2-6/IEC 60068-2-6

Test result

10 Hz ... 57 Hz, amplitude ±3.5 mm, 57 Hz ... 150 Hz, 5g

Type of test

Shock in acc. with EN 60068-2-27/IEC 60068-2-27

Test result

30g for 11 ms, three shocks in each spatial direction

Type of test

Continuous shock according to EN 60068-2-27/IEC 60068-2-27

Test result

10g for 16 ms, 1000 shocks in each spatial direction

Standards/regulations

EN 61000-4-2

Contact discharge

± 6 kV (Test Level 3)

Indirect discharge

± 6 kV

Standards/regulations

EN 61000-4-3

Frequency range

80 MHz ... 3 GHz (Test Level 3)

Standards/regulations

EN 61000-4-4

Comments

Criterion B

Standards/regulations

EN 61000-4-5

Signal

± 1 kV (Data line, asymmetrical)

Standards/regulations

EN 61000-6-4 / EN 61000-4-6

Frequency range

0.15 MHz ... 80 MHz

Standards/regulations

DIN EN 61643-21

Rated insulation voltage

85 V DC

IEC test classification

C2

Conformance

CE-compliant

ATEX

II 3 G Ex nA nC IIC T4 Gc X

UL, USA

UL 60079-0 Ed. 6 / UL 60079-15 Ed. 4

UL, USA/Canada

Class I, Zone 2, AEx nA IIC T4, Ex nA IIC Gc X T4 / Class I, Div. 2, Groups A, B, C, D

UL, Canada

CSA 22.2 No. 60079-0 Ed. 3 / CSA 22.2 No. 60079-15:16

Noxious gas test

ISA-S71.04-1985 G3 Harsh Group A

Function

Designation

Shield current monitoring

Switch-on threshold

≥ 30 mA

Local diagnostics

Yellow LED

Precision

± 5 %

Response time

3 s

Continuous shield current

≤ 1.5 A

Power consumption

270 mW (Shield current monitoring)

Impedance

≤ 1 Ω

Voltage

≤ 10 V

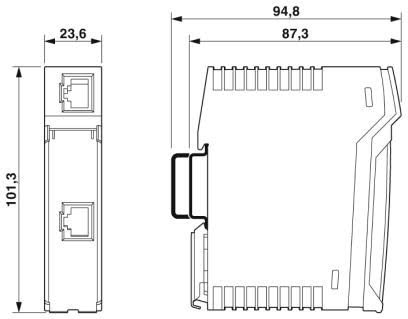

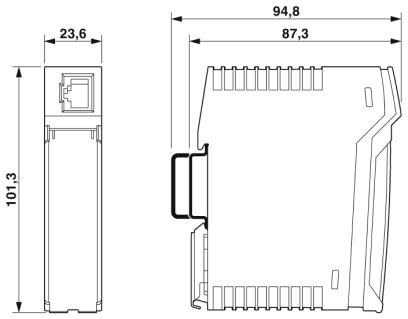

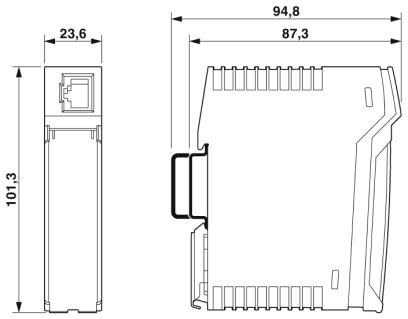

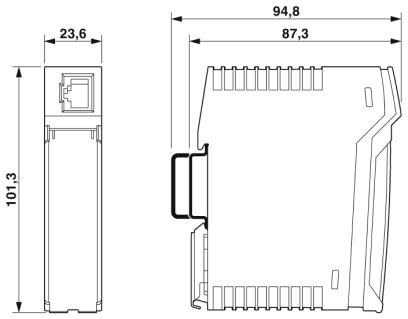

Dimensions

Width

23.8 mm

Height

101.3 mm

Depth

86 mm

Note

Utilization restriction

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

1

PP-RJ-SCC-F

27030228

1

PP-RJ-IDC-F

27030238

1

Power supply

Supply voltage range

PP-RJ-RJ-F

27030208

36 V DC ... 52 V DC 10 % (via PoE (for shield current monitoring))

PP-RJ-SC-F

27030218

36 V DC ... 52 V DC 10 % (via PoE)

PP-RJ-SCC-F

27030228

36 V DC ... 52 V DC 10 % (via PoE)

PP-RJ-IDC-F

27030238

36 V DC ... 52 V DC 10 % (via PoE)

42 V DC ... 57 V DC (With UL approval)

Approvals

- cULus Listed

- cUL Listed

- UL Listed

Environmental Product Compliance

China RoHS

PP-RJ-RJ-F

27030208

Environmentally friendly use period: unlimited = EFUP-e

PP-RJ-SC-F

27030218

Environmentally Friendly Use Period = 50

PP-RJ-SCC-F

27030228

Environmentally friendly use period: unlimited = EFUP-e

PP-RJ-IDC-F

27030238

Environmentally friendly use period: unlimited = EFUP-e

REACH SVHC

PP-RJ-RJ-F

27030208

PP-RJ-SC-F

27030218

Lead 7439-92-1

PP-RJ-SCC-F

27030228

Lead 7439-92-1

PP-RJ-IDC-F

27030238

Lead 7439-92-1

Application Diagrams

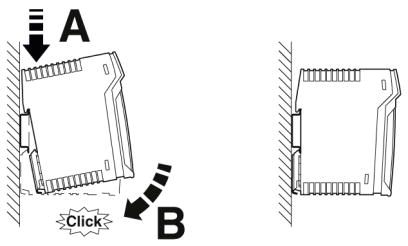

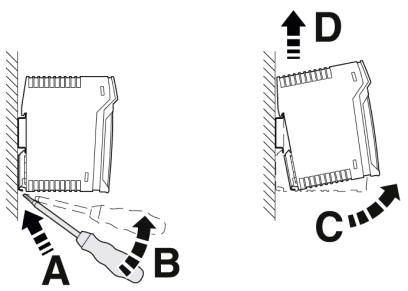

Easily Mount your Patch Panel on a DIN Rail

PP-RJ-RJ-F Patch Panel Dimensional drawing of Compact housing

Two RJ45 Sockets

PP-RJ-IDC-F Patch Panel Dimensional drawing of Compact housing

1 x RJ45 socket and 1 x IDC terminal block

PP-RJ-SC-F Patch Panel Dimensional drawing of Compact housing

1 x RJ45 socket and 1 x Push-in terminal block

PP-RJ-SCC-F Patch Panel Dimensional drawing of Compact housing

1 x RJ45 socket and 1 x IDC terminal block

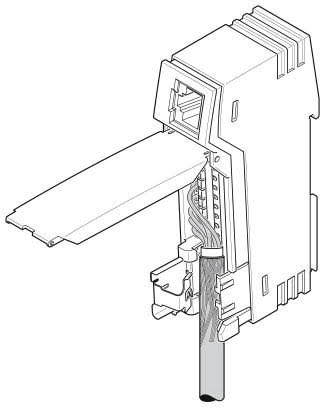

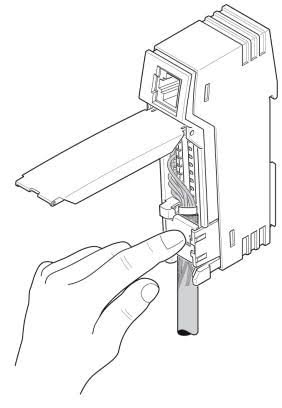

Shield Connection with strain relief

1 x RJ45 socket and 1 x Push-in terminal block

Open shield contact spring

Open shield contact spring Insert the cable

Insert the cable Close shield contact spring

Close shield contact spring

Click on a part number for ordering information

Product Image

Product Description

Power Cord & Part No.

PP-RJ-RJ-F DIN Rail Patch Panel with surge protection: two RJ45 sockets, 10/100/1000 Mbps, IP20, shield current monitoring

PP-RJ-SC-F DIN Rail Patch Panel with surge protection: 1 x RJ45 socket, 1 x screw terminal block, 10/100/1000 Mbps, IP20, shield contacting with strain relief, shield current monitoring

PP-RJ-SCC-F DIN Rail Patch Panel with surge protection: 1 x RJ45 socket, 1 x Push-in terminal block, 10/100/1000 Mbps, IP20, shield contacting with strain relief, shield current monitoring

PP-RJ-IDC-F DIN Rail Patch Panel with surge protection: 1 x RJ45 socket, 1 x IDC terminal block, 10/100/1000 Mbps, IP20, shield contacting with strain relief, shield current monitoring