Ethernet can provide the core for robust vision networks

By Donna DonnowitzOctober 18, 2011

Vision networks are emerging as a key technology in the manufacturing sector. They give businesses the tools they need to automate product inspection, creating the oversight necessary to ensure quality throughout the production process. However, vision networks are complex and difficult to establish and automate unless organizations deploy sophisticated network infrastructure to support the inspection tools, Control Engineering reported.

Essentially, a vision network is designed to automatically inspect products as they come through the assembly line and transmit that data to devices where it will be put into use for quality control and assessment. This means that large quantities of information are commonly sent through the network because an automated vision system is generally capable of working much faster than human inspectors, the report said. Contemporary vision technology enables the assessment of every good manufactured in a facility. The amount of data required to handle this process is vast and robust Ethernet architectures are needed to transmit that content throughout a facility.

Establishing Ethernet infrastructure to support vision networks requires careful planning and investment in sophisticated technologies. According to the news source, vision systems can be based in computers or within specialized cameras, and factories require advanced capabilities to support the diverse range of devices used to support product inspection. While Ethernet is key to support data transmission between devices, it has also emerged as a key interoperability tool.

The report explained standards that emerged in 2006 established a system in which Ethernet infrastructure can be used to support interoperability between devices. This allows cameras, computers and other vision-related tools to quickly communicate with each other and leverage advanced image processing.

Ethernet has also emerged as a tool for input/output, lighting and triggering systems in manufacturing settings, making it a critical technology for the sector. Power-over-Ethernet has been especially beneficial in industrial settings, as it reduces the number of cables needed to support cameras, computers, lighting systems and other important factory technologies, according to the news source.

Industrial Ethernet in all of its forms is rapidly emerging as a key technology to support a variety of manufacturing tasks. A recent Automation World report said the value of robust networks in industrial settings is rising. The growing importance of such systems comes as Ethernet technologies develop and the demand for the technology at the device level rises.

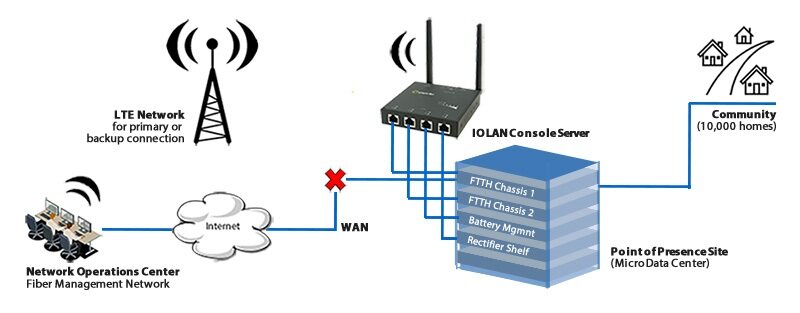

Perle’s serial to Ethernet converters connect serial based equipment across an Ethernet network. The Perle IOLAN range of Console Servers, Device Servers and Terminal Servers feature built-in support for IPv6 along with a broad range of authentication methods and encryption technologies.