Integrated architectures paying dividends in automation sector

By Max BurkhalterJanuary 31, 2012

Historically, manufacturing automation has been built on a diverse range of IP systems and networking protocols in an effort to precisely optimize the various aspects of machine automation. This is changing quickly, as Ethernet's maturation has created an environment in which automation and data networks can be integrated into a single architecture that dramatically improves the manufacturing process, Process & Control Engineering reported.

According to the news source, an integrated architecture can provide the level of interoperability between data and control systems necessary to completely revolutionize how a factory is run. Essentially, the integrated system is capable of streamlining every aspect of the information management and production elements of the manufacturing processes.

The problem is, according to some past presuppositions, is that many manufacturers believe that integrated architecture systems can only function within large manufacturing environments. The report said this assertion has been proven false, as advanced networking and automation tools have emerged to create a scalable solution that can be adapted to meet the specific operating needs of almost any type of production environment.

Furthermore, integrated architectures are now capable of handling motion, drive control, safety, process and data aspects of the automation deployment. This is possible because Ethernet infrastructure is used to handle all of the various capabilities, allowing the same infrastructure to be used to transmit both data and control-related content, the report explained.

All of these factors combine to create an infrastructure in which more devices can be interconnected, more monitoring systems can report to a diverse range of destinations and the ability to maintain manufacturing environments is improved. According to the news source, this subsequently leads to a reduction in operating costs and creates an environment in which all operations are streamlined.

Ethernet's ability to support more efficient operations is happening in a variety of sectors, not just manufacturing. In the data center, a growing number of operators are converging data and storage network infrastructure. Traditionally, two separate networks were needed to handle the amount of bandwidth being sent through the facility to end users. While the data throughput requirements are rising, Ethernet performance is also improving. This is leading to an environment in which a high-performance converged network is often more effective than multiple mid-level setups that handle data transit and storage separately.

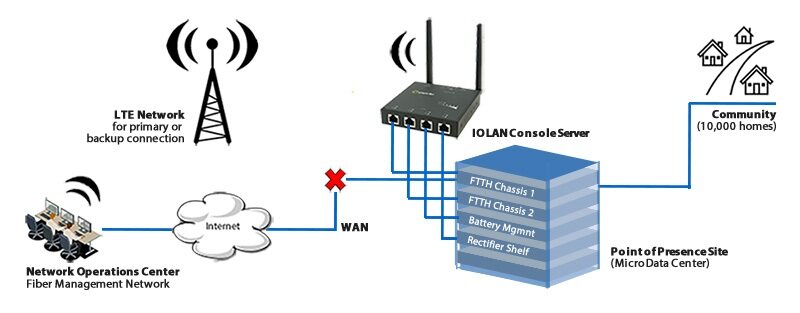

Perle’s serial to Ethernet converters connect serial based equipment across an Ethernet network. The Perle IOLAN range of Console Servers, Device Servers and Terminal Servers feature built-in support for IPv6 along with a broad range of authentication methods and encryption technologies.