Networking needs continue to evolve

By Max BurkhalterDecember 16, 2013

Industrial and production networks continue to evolve closer to IT networks as businesses instate automation and other efficiency efforts and solutions. However, the interplay between legacy systems and these new networks often changes the expectations of network performance and support, with increased need for secondary investments to ensure that hardware can connect with improved Ethernet cabling properly - such as an RS232 to Ethernet converter.

According to Process and Control Engineering, today's manufacturing network has evolved significantly since businesses began using production networks in the '60s. Process automation technologies were introduced in the 1980s that revolutionized operations, while LAN and WAN support continues to improve to today. More individual pieces of equipment have become networkable as well, providing more opportunities to improve and automate workflow.

The biggest change was the development of the industrial Ethernet in the mid 1990s. The news source reported that industrial Ethernet quickly over took industrial networking, becoming the standard for ease of interoperability and open standard protocol compliance. This shaped what manufacturing and processing networks have become today, delivering higher capacity and speeds up to 20,000 times the stability of networks 15 or 20 years prior.

"The Ethernet port is a given as a PC interface, suiting both industrial and office networks, and eliminating the need for costly interface hardware. Ethernet has provided high-capacity networks, with 1Gigabit data rates now common – a multiple of some 20,000 times the common network rates of 15-20 years ago. This glut of capacity provides for network convergence, accommodating data and voice/video sharing the same cable," Mark Elrick, a senior consultant on automation, electric and networks who has been in the industry since the '80s, explained to the news source.

Ultimately, the greatest gain achieved through investments into improved serial to Ethernet technologies and the overall industrial networking movement is improved visibility and accuracy in operations. Steven Sischy, another industry expert, noted that the merger of IT technologies with these networks has provided automation and remote access support that reduces costs and boosts security, ease of connectivity and control across the globe. These benefits help firms run cheaper, more efficiently and at greater production volumes than ever before.

In order to truly gain these advantages and optimize automation and growth, companies have to invest in the media converter technology that supports these changes and delivers the speeds and remote I/O capabilities that make them possible.

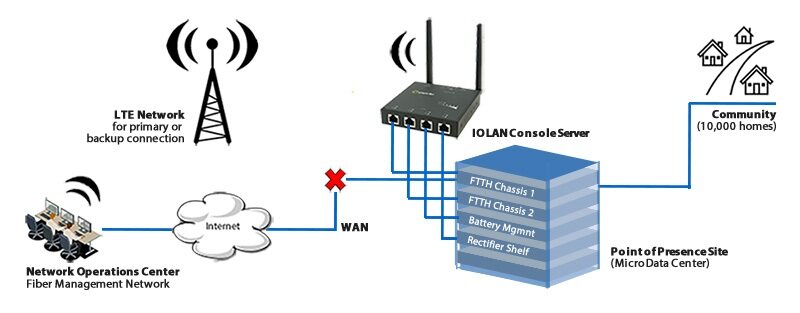

Perle's serial to Ethernet converters connect serial based equipment across an Ethernet network. The Perle IOLAN range of Console Servers, Device Servers and Terminal Servers feature built-in support for IPv6 along with a broad range of authentication methods and encryption technologies.